There is no doubt that poured-in-place rubber is a fun and exciting surface for playground enthusiasts to run around on. Kids surely will appreciate the nice response of the rubber cushioning propelling them forward as they run and play.

Yet, what happens when cracks emerge in the wear layer? The poured rubber surfacing is bound to crack, literally, which can lead to safety issues for kids that trip over the hole in the wear layer.

Poured-in-place surfaces contain a top layer that can be 3/8″ to 1/2″ thick, and when this layer cracks, watch out for the pitfalls.

The Four Phases of Poured-In-Place

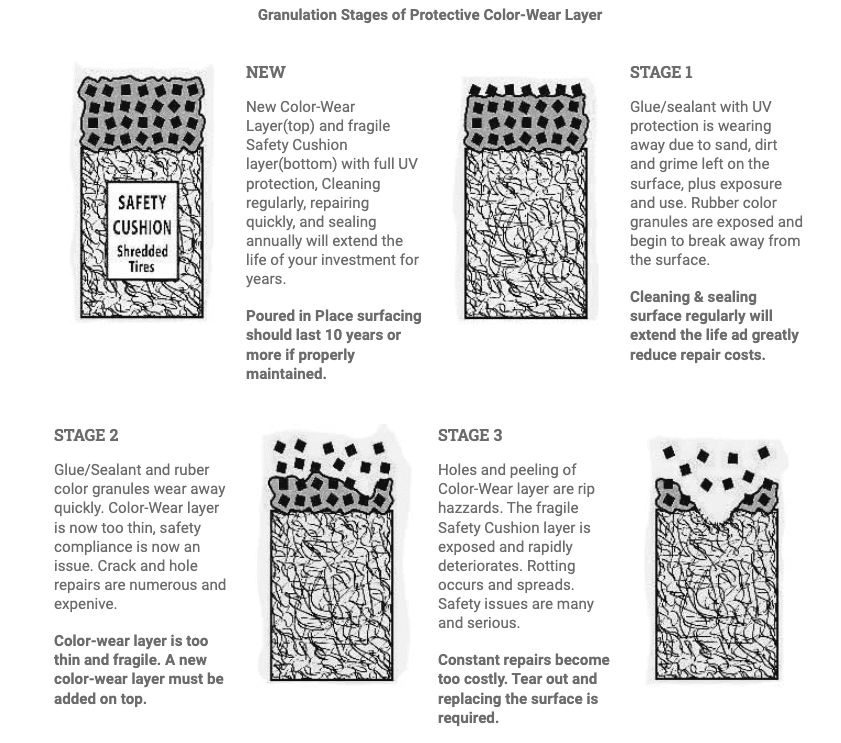

According to Creative Recreational Systems, there are four phases in which poured-in-place evolves over time.

New, product functions as intended and looks great.

Stage one, the product is wearing down due to dirt and grime, and rubber granules are exposed.

Stage two, poured-in-place rubber wear really starts to show. The rubber wears away quickly, along with glue and color fading, leading to holes and general degradation.

Stage three, the solid rubber surface starts to show its cracks, literally! Holes, peeling, rotten material, big gaps, and expect a big bill to repair.

The Rubber Mulch Advantage

Rubber mulch as a loose-fill surface allows you to easily rack over degraded spots, and put things like highly durable swing mats in other traffic areas.

The cost per square foot is much less for loose-fill rubber rather than poured in place, on new installs and atop an existing surface.

A Costly Surface to Repair

How costly is poured in place rubber to repair? Without taking into account labor, training if needed, and equipment, the materials alone can run into the hundreds if not thousands of dollars.

Poured in place rubber needs a specific glue and covering materials like binder, conditioner, top coat, and even sub layer crumb rubber surfacing. All of these materials can quickly add up in overall cost.

Rubber playground cost per square foot when it comes to flooring will depend so much on what type you end up purchasing.

The cost per square foot for poured rubber is significantly higher than engineered wood fiber, wood chips, and loose-fill rubber, contributing to the poured in place rubber cost.

Why Pour In Place Rubber is So Bouncy

Rubber surfaces like poured rubber typically have a base layer and then a top layer, equaling two layers, which helps with impact attenuation and fall safety. These several factors lead to a bouncy responsive material per square footage, and can vary depending on the bonding agent used as to how long they will keep the desired color before degradation.

However, the poured in place rubber base layer will be exposed as the half inch wear layer appears with time, leading to a long-term cost higher than the initial cost. Even inch-thick base layer rubber flooring will lead to degradation over time. This is a safety issue that could become a liability if high traffic areas are not consistently maintained on the poured in place rubber surface.

The Liability Issue

Beyond the cost to repair poured in place rubber surfacing is the real big risk, liability. If playground surfacing is damaged and child falls and hurts themselves, who then is ultimately responsible for the injury?

Safety should be top of mind, and thus PIP can present a conundrum for schools, parks, daycares, and churches thinking about installing the surface.

We are not lawyers here, but certainly, there would be an expectation that a playground with a rubber surface is properly maintained and up to code if it were a school, daycare, church, or municipality.

Consider poured rubber playground cost as a mix of the initial cost for the square footage, upkeep, and maintenance cost for the poured rubber, and finally, liability cost for the holes and trippable areas of the poured rubber surfacing that appear over time.

Resealing Costs for Poured In Place Rubber

Rubcorp recommends resealing the poured rubber flooring every two years. According to Trassig, the cost could be $1 to $1.50 per square foot. So a 4,000 square foot playground surfacing job would run $4,000 to reseal every two years, or budget-wise it would be a whopping $2,000 per year in maintenance costs – and that’s just for the reseal. You could be looking at additional costs per square foot depending on the wear of the sub layers, and other factors like having to remove equipment or repair mounting hardware.

Save money on aromatic glue, binders, base layer, and more by choosing a loose-fill surface like mulch.

ADA Compliant

While loose-fill mulch is ADA compliant, poured in place rubber typically offers greater smooth surfaces for playgrounds. This can help with more playground safety as the wet pour rubber surface eases the friction of a wheelchair wheels on the ground compared to loose-fill.

What’s Under The Poured Rubber Playground Surface?

Could it be dirty chopped-up tires? The base layer of rubber surfacing under the playground equipment is often crumb rubber. When wear layers appear this dirty rubber tire mulch is exposed for all to come into contact with.

If you look closely at the picture we included at the top of this blog post, you can see the layers of rubber thickness, including the recycled rubber tires. This is commonplace for rubber surfacing materials such as poured-in-place rubber.

The Best Cost-Effective Alternative to Poured-In-Place Rubber Surfacing – Mulch

Loose-fill non-toxic virgin rubber mulch like Jelly Bean is the absolute best solution to avoiding costly repairs.

The rubber flooring is easy to install, heavy enough to stay put in storms, non-toxic, easy to rake, and fun for kids to play atop of. There is no wear layer that cannot easily be raked over or supplemented with a mat.

Compared with poured rubber flooring Jelly Bean offers significant opportunities to save money, from the cost of the product to the simple installation, to the repair time and resource cost.

Best Uses For Poured-In-Place Rubber

While not always the best for larger playground flooring projects, PIP can be valuable as a surface for pool decks, amusement parks, water parks, and small playgrounds with a big budget.

Think About Cost When You Need To Repair Before You Buy

It is not if, but when nearly all playground surface installs will need repair, regardless of the product.

For all the hype over the unlimited design potential of poured in place rubber surfacing, there is less talk about the cost of maintaining such a surface.

Safety

Yes, the impact attenuation of the poured rubber surface is high, and the shock absorption is excellent, but that comes at a cost.

Playground mulch also has a highly rated impact attenuation, and yet no bonding agent is needed for such surfacing materials.

Wet pour rubber that is sold in a compacted aggregate quart or five-gallon bucket is available for repairs, will cost more than other options, like simply raking the loose-fill mulch, or ordering a top-off.

To sum it up, consider the true cost of poured-in-place rubber before buying.